Window Mounted Drone Port

Unmanned Aerial Vehicles, aka Drones, can be useful for rapid delivery of goods to retail customers. A vision for Drone Based Deliveries is published here. The vision is to have fully autonomous drones deliver small items to customers in densely populated metro areas. Each package would typically be limited to about 8 pounds and be smaller than a 9-inch cube. Once an order is placed, most of the fulfillment steps can be automated. The loading of items onto a drone can be done with minimal human intervention. Customers need not be present to receive deliveries.

As described, a key requirement for the success of that vision is a delivery point at the customer's site. A customer who resides in a multi-story apartment complex may not have a convenient point where they can receive drone deliveries. Even suburban dwellers may not want deliveries dropped on their driveways or backyards. They will need a delivery point like the Drone Port. Vendors can use this device to originate deliveries. This note details the Drone Port.

Operation

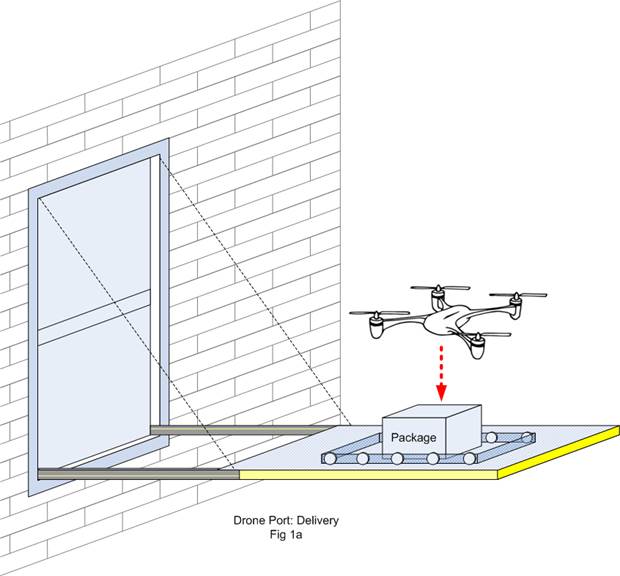

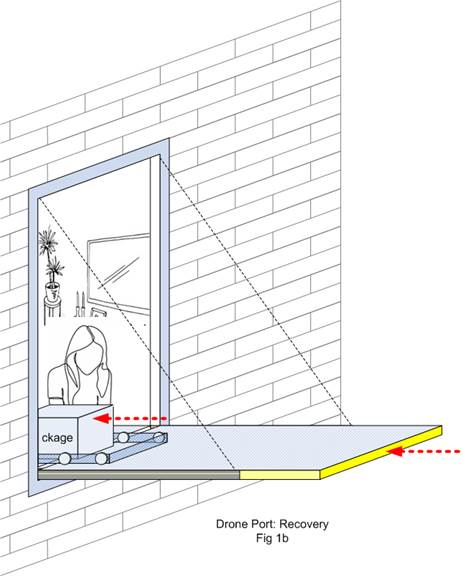

This section describes a method to make a "drone delivery port" out of an ordinary window. Most people have a room with a window, even in apartments. If the outside of the window can be accessed by a drone, it can be used as a suitable delivery point. It provides a safe, secure, and convenient delivery (or pick-up) point for drones. Drones can load and unload their cargo here. The window can be on any floor, but it must be possible to navigate to it while avoiding nearby obstacles like awnings, power lines and trees. Figures 1a & 1b show the Drone Port in operation.

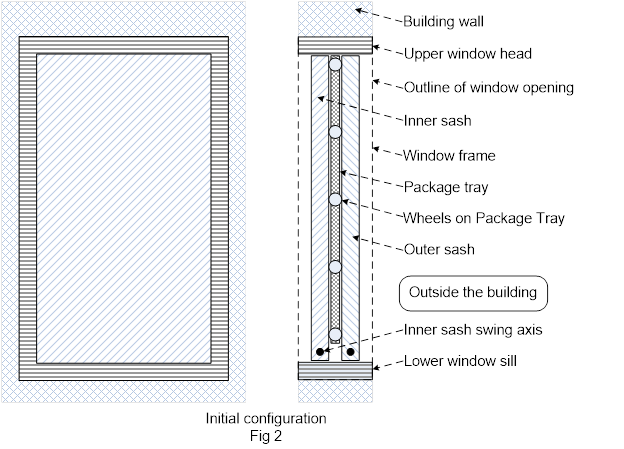

This Drone Port comprises two window "sashes", a package tray, and a control system. The term sash refers to a panel that covers the opening of a window. It will typically be a glass pane in a frame. Each of the two window sashes can independently swing around their bottom edge to open and close. The outer sash can swing outwards to form a horizontal delivery pad for packages. It can be extended further away from the wall to allow more maneuvering room for drones. Drones can approach, deliver a package on this pad, and fly away, as shown in Fig 1a. They may actually land on the delivery pad or may drop off the package while hovering over the pad. After a package has been delivered, the inner sash can swing open inwards to form a horizontal reception shelf. The package is moved indoors on to the inner sash, as shown in Fig 1b. The outer sash can then swing to close the opening and keep the weather out. The package is now safely indoors on the inner sash until it can be retrieved by the customer. When the package is removed, the inner sash can swing shut. The entire operation can be completed in less than a minute.

The sequence of steps can also be reversed to allow package pick-up by a drone. This allows goods to be returned by customers and allows vendors to originate goods for delivery to others. In this case, the inner sash can swing open first and the package is placed on it. When the drone arrives, the outer sash can swing open, and the package can be moved out on to it. The inner sash can then swing shut. The outer sash can swing shut after the package is picked up by the drone.

The package tray helps the package slide smoothly through the window opening. It can move horizontally over the sashes. It may be driven using cables, motorized wheels, conveyor belts or some other mechanism. When it is not moving, the tray will be firmly anchored to one of the two sashes. The movement and latches will be managed by the control system. It can be stowed between the inner and outer sashes when the Drone Port is not being used. The tray may have small collapsible vertical fences along its edges to stop the package from falling off. The delivery target on the tray can be marked with LEDs, QR coded identification, and other navigation beacons.

Control System

The control system manages the movements of the sashes and tray. It also communicates with the sender to validate the delivery, and with the drone to guide it during approaches and departures.

Security & authentication protocols implemented by the in the Control System will help validate the drone, the Drone Port and the sender. The package manifest (origin, destination and contents) provided by the sender will determine if the delivery (or pick-up) is authorized. This will help prevent unwanted 'spam' and 'junk mail' deliveries and will provide a delivery confirmation to the sender. Each Drone Port can be cryptographically associated with a recipient. Emergency Access and Law Enforcement overrides can be supported.

The Control System will publish the Drone Port's weight and size limits. This will constrain the payload. The current Drone Port status will indicate whether the port is available and will help schedule of the delivery flight. The Control System will provide position information (coordinates, altitude, nearby hazards) and local weather to the drone's originating point. This is analogous to a NOTAM broadcast by airports. It will also provide the optional navigational features that it supports (wind gust sensor, ultrasonic position sensors, beacons, LEDs, approach path lighting, etc.). This information can be used to select an appropriate drone.

The Control System can communicate directly with the incoming drone when it is close by. This will allow it to open the outer sash to prepare for delivery. It can also allow it to provide optional instantaneous weather conditions or terminal guidance to the drone.

A standardized communications protocol can be used to coordinate the overall flight paths of drones. Though such a standard does not currently exist, the FAA's Unmanned Aircraft System is evolving. This protocol may not involve the Drone Port, it is mainly between drones and the local flight control authority.

Optional Enhancements

The Drone Port can be visually transparent to preserve the function and appearance of a window. The sashes and the tray can be made of a tough but transparent material. It can also be designed to match the exterior appearance of the building and be generally undetectable from the outside, except when it is in operation.

Each movable sash in the Drone Port may cover the whole window or may cover part of it, for example, only the lower half may swing out. This would reduce the space occupied inside the room by the inner sash.

The sashes and tray can be deployed and closed using cables driven by a motor.

An optional mechanism can move a delivered package from the tray to an adjoining platform. This would free up the Drone Port for additional unattended deliveries.

The Drone Port can include a load sensing or self-leveling mechanism to counter the effect of heavy packages or the rotor wash from departing drones.

The Drone Port can be equipped with LED infra-red lights to guide the drone to its target. The LEDs can be placed along the edges so that they are not obstructed by a package.

The Drone Port can provide lighting for drones' approach paths to help with visual navigation at night.

The Drone Port can be equipped with sensors that can provide fine navigational guidance to the drone, including but not limited to ultrasonic, optical and audio sensors.

The Drone Port can be optionally equipped with wind sensors to detect adverse wind gusts that may impact the drones' operation near the walls.

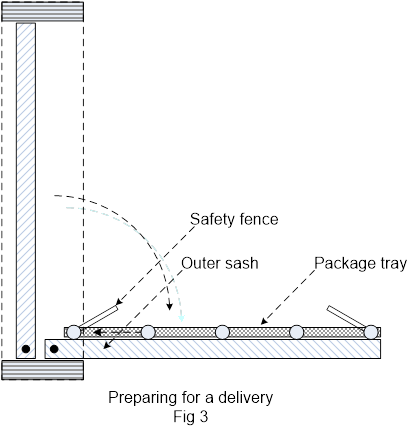

The Drone Port can be equipped with safety features to prevent accidents and ensure the safe operation of the drones. For example, the package support pad can be surrounded by a safety net to prevent package and drone debris from falling to the ground. The package tray can be fitted with retractable fences at its edges to secure the package.

The Control System can keep logs of its activity and send notifications about various events, for example, package deliveries, various failures, etc.

Mechanical Details

The main physical components of a typical Drone Port are depicted in Fig 2. It shows the components in their folded state while the Drone Port is not being used. The exterior wall extends vertically above and below the depicted window sills. The building interior is to the left of the figure and drones approach from the right. There is an exterior and an interior window sash, each of which can independently swing around their respective horizontal swing axis to open and close. The outer sash opens outwards and the inner sash opens inwards. When opened, both sashes present a horizontal surface. The outer sash can be extended away from the wall using a mechanism like drawer slides. This allows more clearance for drones. A sash can cover the entire height of the window or part of it. Sashes can have weather seals which are not shown. The mechanism for autonomously moving the sashes is also not shown.

Fig 2 also depicts the Package Tray stowed vertically between the two sashes. It is the sliding mechanism on which packages are placed. A drone will place an incoming package on it, or will pick up an outgoing package from it. When both sashes are in their open, horizontal position, they will be at the same level and the tray can move from one sash to the other. This allows the package to be moved from outside to inside, or vice versa. The tray can be moved in a variety of ways, including tray mounted wheels or treads in a channel. Alternatively, it can use sash mounted wheels or conveyer belts. The wheels can be motorized or the tray can be pulled by cables. The tray can have collapsible safety fences along its edges to prevent the package from falling off while the tray is moving. The Control System controls the movement of the package tray.

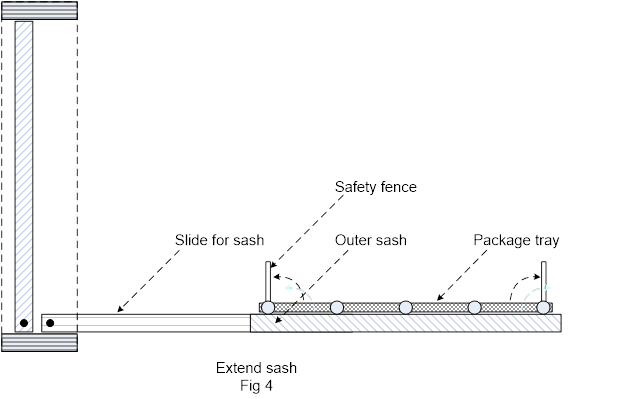

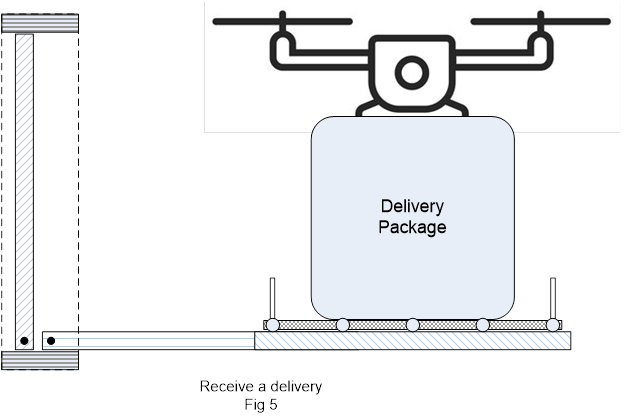

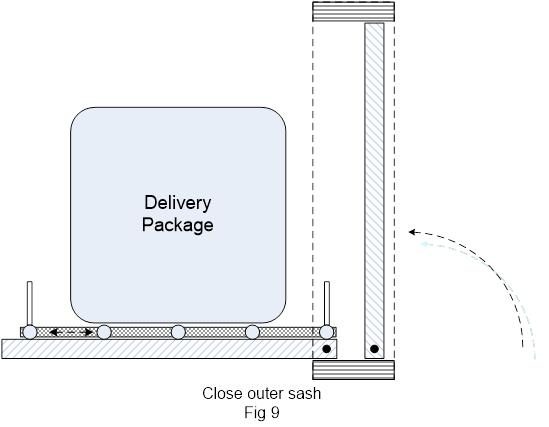

Figures 3 through 9 depict a sequence of transitions made by the Drone Port to receive an incoming drone delivery. Fig 3 shows the first step to receive an incoming delivery. When the Control System detects the drone within range, it opens the outer sash. The Package Tray is locked to the sash and moves with it. The Safety Fences on the tray start to deploy. Fig 4 shows the outer sash extending away from the building on a set of slides. A number of navigational aids can be activated to help the drone position itself over the tray. Fig 5 (and Fig 1a) shows the package safely delivered on the tray. The safety fences are fully deployed. The drone departs after completing its mission.

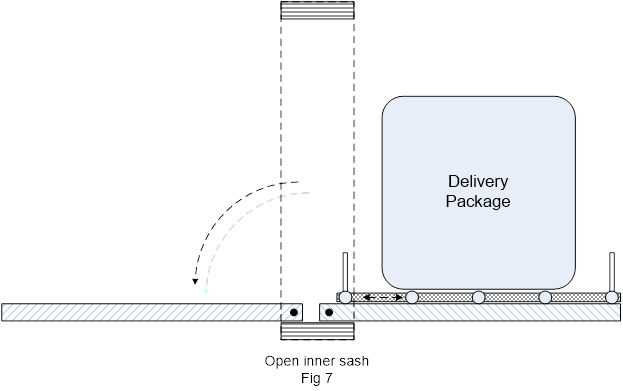

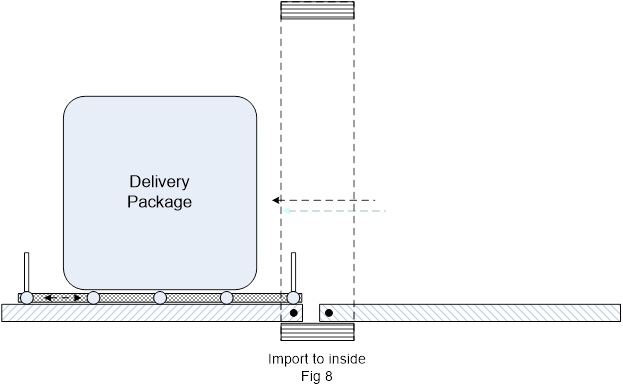

The next step is to bring the delivered package indoors to safeguard it and protect it from the weather. Fig 6 shows the outer sash retracting back. Fig 7 shows the inner sash open, and Fig 8 (and Fig 1b) shows the package moved indoors. Fig 9 shows the outer sash closing. The package can rest on the horizontal inner sash until it is removed by the recipient. The Control System then moves the inner sash and the tray back to their initial vertical position, as shown in Fig 2.

The sequence of steps can be reversed to allow for packages to be picked up and taken away by a drone. As shown in Fig 9, the inner sash is first opened. The Package Tray is locked to the inner sash and the safety fences deploy. The package to be picked up is placed on the tray. When the Control System detects the approaching drone, it opens the outer sash as shown in Fig 8. The tray carrying the package is moved outside as shown in Fig 7. The inner sash is then closed as shown in Fig 6. The outer sash can be extended to be more easily accessed by the drone as shown in Fig 5. After the drone picks up the package (Fig 4), the outer sash is retracted (Fig 3) and then closed (Fig 2) to return the Drone Port to its initial position.

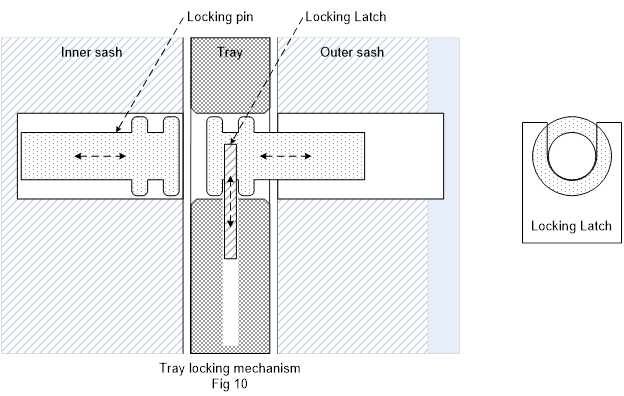

Fig 10 depicts one way of firmly locking the Tray to a sash when it is not moving. The two sashes and Tray are shown in their vertical position. A Lock Point comprises a Locking Pin in the sash, a Pin Orifice on the Tray, and a Latch inside the Tray. The Pin is pushed into the matching Orifice in the Tray and the Latch inside the Tray is moved to clamp on to the Pin. There will be multiple Lock points distributed around the tray which will activate simultaneously. Releasing the lock involves first retracting the Latch and then retracting the Pin. The mechanisms to drive the Pin and Latch are not shown but are activated by the Control System. Each Pin can be moved by a solenoid which is not shown.

Conclusion

The lack of secure and convenient delivery points for residential customers is also critical but has not been widely recognized. A lot of effort is being made to solve other aspects of drone delivery, but no one seems to be thinking about the delivery technique.

©2023 Rajaram Pejaver 731

Patent pending, 2023

Cue Group, LLC